Last week, researchers and directors at WUR and the Technical University of Eindhoven (TU/e) presented their plans for making food production in the province of North Brabant more sustainable, working together with HAS University of Applied Sciences and the agricultural organization ZLTO. Within the new AgriFood Innovation Initiative which was launched officially on 13 May on the Eindhoven campus, researchers are going to put their heads together to see how they can make better use of plant waste, improve the welfare of pigs and further develop precision agriculture (see inset). ‘The link between WUR and TU Eindhoven on the agri-food-hightech axis is essential to North Brabant,’ the province writes about the initiative.

Hands-on mentality

Hightech and agri-food are joining forces with increasing frequency. And this hasn’t come out of the blue. Three years ago, WUR joined the collaborative federation of the science universities of Delft, Eindhoven and Twente, turning 3TU into 4TU. The favourite collaboration partner for WUR is Eindhoven, a university which focuses its high-tech research on health, energy and mobility, and sees opportunities in the field of agri-food. Two leaders were appointed to explore the scope for collaboration: Ernst van den Ende, director of Wageningen’s Plant Sciences group, and Jakob de Vlieg, professor of Applied Data Science at Eindhoven. Asked about the state of play, De Vlieg reels off a long list of joint WUR and TU/e projects. Some have already started, some are about to start and for some, proposals are being submitted (see insets).

There is a lot of contact, especially, between the boards of Eindhoven and Wageningen. That is because there is a lot of common ground between their lines of research, said the Wageningen rector Arthur Mol last year in Cursor, TU/e’s online magazine. ‘Also, our universities are very similarly organized: a lot is left up to the people at the workface. We don’t have researchers with inflated ideas about their own importance; we have people with a hands-on mentality.’

We both have researchers with a hands-on mentality

Speaking the same language

Things don’t always run smoothly, however. Wageningen and Eindhoven collaborate in the Sustainable Food Initiative, a large consortium of universities and food companies that want to make their production more sustainable. But the approved SFI projects have not started yet, because the companies have not reached an agreement on who owns the knowledge to be developed. De Vlieg: ‘Sometimes we work on big research proposals involving several parties, in which we have to agree on a lot of things in a short time. That can be tricky.’

The biggest issue for the collaboration, according to De Vlieg, is whether the researchers speak the same language. ‘We need good interdisciplinary questions,’ he says. It is also essential that the researchers appreciate each other’s qualities, adds Van den Ende. There have been times when Wageningen Research staff implement a project with TU/e professors who have never done applied research, says Van den Ende. ‘Then you need to make good use of each other’s competencies.’

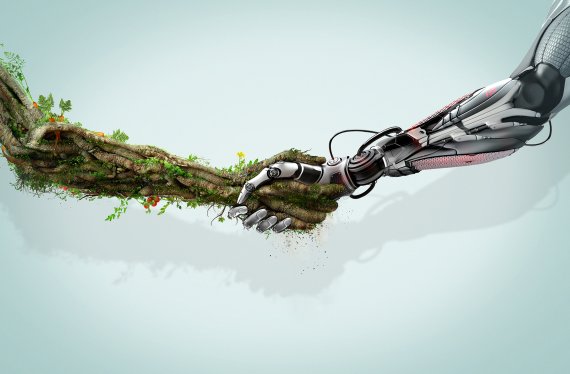

De Vlieg has seen the collaboration grow. ‘You see, Eindhoven has a lot of expertise in the fields of robotics, sensing technology and artificial intelligence. Wageningen is the best in the world in agri-food. That brings a lot of energy into the collaboration and creates new scientific opportunities. I have seen a big increase in interest in agri-food in Eindhoven, among students as well.’

Duurzaam voedsel verbouwen

Within the new AgriFood Innovation Initiative, WUR and TU Eindhoven are going to help the province of North Brabant make food production more sustainable. One of the ways they plan to do this is to research how to make better use of plant waste flows. They will use new extraction and drying techniques to process carrot scrapings into valuable juices, fibres and pectin. That is big business in Brabant, where nearly half the country’s carrot crop is grown. The researchers are also going to develop new sensing, visual and data methods for measuring the welfare of pigs. In this project aiming at a ‘smart pig chain’, they will also look at the potential for innovative sheds, breeding methods and adapted feeds for improving the animals’ health. The aim is to reduce the use of antibiotics and improve the quality of the meat. This is another important issue for the province, where 1600 pig farms rear half of all the pigs in the Netherlands.

And a third project focusses on precision agriculture in the potato sector, in the interests of more efficient use of water, nutrients and pesticides. Wageningen and Eindhoven are going to pool expertise in the areas of model development, data interpretation and the design and development of smart machines.

Purification by lightning

Plasmas are ionized gases in an electric field. They are at work in a flash of lightning or in fluorescent tube lighting. The Eindhoven professor Guus Pemen makes plasmas for medical and environmental applications. If, say, you conduct dirty air through a machine which generates little lightning flashes, you get clean air. The professor thinks this could be of use to the agriculture sector and he is now running a pilot project to capture ammonia, fine particles and bacteria in pig sheds using plasma technology. Together with Masja Nierop Groot of Wageningen Food and Biobased Research, he is also running a test to reduce rotting in potatoes in storage by capturing the rotting gas ethylene with plasmas. The technique works in both cases, but it is still much too expensive.

Pemen is also working on deriving artificial fertilizer and pesticides from plasma-activated water. If you create mini lightning flashes above a bowl of water, a whirlpool is formed in the water containing all sorts of nitrogen and oxygen free radicals. Under certain conditions, nitrate is then formed – which is artificial fertilizer. Under other conditions, disinfecting compounds are formed which can combat fungal infections. Pemen has tested this plasma water on pepper and strawberry plants at WUR Greenhouse Horticulture in Bleiswijk, and managed to combat fruit rot with it. Pemen has now written an NWO proposal together with WUR, for research on the effect of plasma-activated water on plants. ‘I need WUR because I don’t know anything about strawberries or microbiology.’

Food from the printer

For a year, WUR has been working with TU/e and the Netherlands Organization for Applied Scientific Research TNO on the Digital Food Processing Initiative. Coordinator Katja Pahnke of TU/e: ‘Eindhoven is good at printer technology; Wageningen is good at nutrition; TNO is good at development processes. We are working together on research proposals on printed food.’ One PhD student is already working on the structure of printed food. You could produce carrots, for example, in the form of a smoothie, suitable for elderly people who have difficulty chewing or swallowing, says Pahnke. Or you could print an appetizing insect burger, or personalize food for people with allergies.

Mini-spectrometer

Plants absorb light of a certain wavelength. Spectrometers can use that fact to measure things like the length of leaves or the sweetness of strawberries. So far, these have been relatively large and pricy pieces of equipment. The Eindhoven professor of Photonics, Andrea Fiore, wants to create a small, cheap chip that can do exactly the same thing, and could be put in a smartphone. Fiore already knows how he can measure light with this kind of microspectrometer, and which filters he can use to convert the different wavelengths into information. What he doesn’t know is exactly which wavelengths provide which information about the plant, and how sensitive the filters need to be. He therefore wants to collaborate with the Wageningen Imaging Spectroscopy Hub (WISH). The collaboration is still in its infancy, but Fiore anticipates doing fundamental research and fieldwork in greenhouses together with WUR.’

Robot picks apples

Together with other universities, Eindhoven and Wageningen are participating in the NWO programme Flexcraft, in which researchers are developing new robots. The research leader is Professor Eldert van Henten of the Farm Technology Group at WUR. Flexcraft has four million euros to spend on robots which do things like pick ripe apples and tomatoes or pack chicken filets at the abattoir.

Smart organic farming

WUR and TU Eindhoven have teamed up with the Universities of Delft and Utrecht to submit a programme proposal called Synergia to the NWO. In this programme, they want to use hightech in the interests of efficient ecological farming. Concretely, they want to develop robot systems for methods including mixed cropping and strip cultivation. ‘We are world leaders in robotics at the TU,’ says De Vlieg. ‘To get the robots working together, we use a variety of sensing techniques and artificial intelligence. We hope to use this knowledge in arable farming too, for example for targeted weeding and to make making mixed cropping economically viable.’ Peter Groot Koerkamp, professor of Agrotechnology at WUR, took the initiative for this project at the cutting edge where agriculture, horticulture and hightech meet.

Spying on turkeys

Peter de With, expert in computer vision at the TU Eindhoven, is going to do research with the Wageningen animal scientist Piter Bijma. In collaboration with Hendriks Genetics, they want to track the individual behaviour of turkeys in large barns using cameras. To do this, they need to be able to tell hundreds of individual animals apart. De With developed detection methods for health care, for recognizing tumours, and is now going to see whether his technology can be used in livestock farming too.

On-farm milk processing

The faculties of Industrial Design and Information Engineering in Eindhoven are keeping each other busy with new concepts for short food supply chains. Examples are an on-farm milk factory for processing milk fully automatically and highly specifically, or personalized milk per cow. The faculties would like to continue developing these concepts in collaboration with Wageningen.

Illustration: Jeroen Murré

Illustration: Jeroen Murré