For the past three years, PhD candidate Sophie van Lange has been dedicated to one clear goal: producing plastic that is both hard and sustainable. The plastics we use today are either recyclable or robust – not both. She threw some physics into the chemistry-based quest, which enabled her to develop a new kind of plastic that is both hard and recyclable: compleximers.

Ironically, the process doesn’t seem very complex at first sight. It is based on two separate powders, one white and one yellow. In the Physical Chemistry and Soft Matter laboratory, Van Lange dissolves these powders and combines the two solutions. Slowly but surely, flakes of plastic form, and after a series of washing and drying steps, a yellow powder remains. She pours this carefully into a mould and places it in a hot press on a hot plate. She then pulls on a large handle to press the powder together under high pressure and heat. And there it is, hot off the press: a piece of compleximer. Hard and yet easy to reshape.

Health food store

Let’s rewind 10 years, to a Friday evening in a health food store in the little town of Baarn. Shelves loaded with organic products and a fruit & veg section with bell peppers, cucumbers, broccoli and carrots. No plastic packaging in sight. Sophie van Lange, 16 at the time, is working on the checkout. She doesn’t realize it yet, but a seed is being sown in her mind. Doing this side job is making her increasingly aware of sustainability, an ethical relationship with nature, and the functional uses of plastic.

Two years later, her interest in sustainability takes her to Wageningen University. There, and on her Master’s programme in Eindhoven, she learns how much plastic we actually produce: over 400 million tons a year. ‘I saw how much gets lost in that process,’ says Van Lange. A machine pours plastic into a mould, but the bits at the end have to be cut off and binned. What is more, only a small proportion of all the plastic gets recycled. Nevertheless, Van Lange doesn’t see plastic as the enemy. ‘We can’t do without it: it’s in the shoes I’m wearing and in my glasses,’ she says, pointing to her pink spectacles frame. ‘But it would be great if we could process all plastics sustainably.’

Physical forces

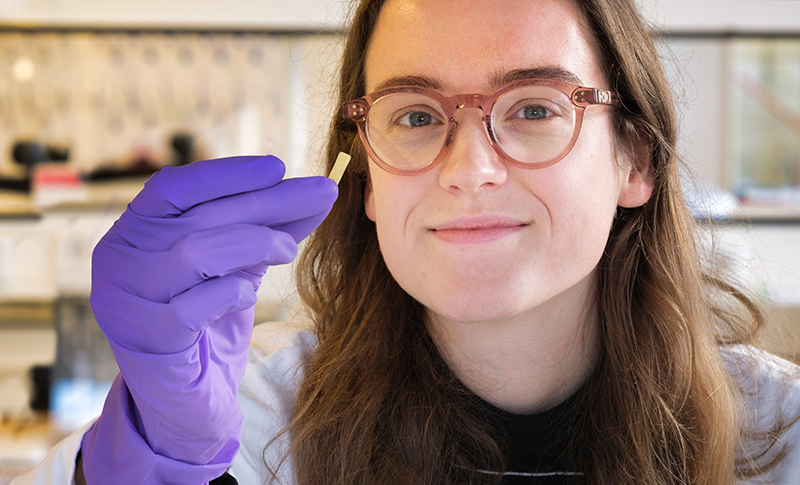

After a three-year quest, here it is: Van Lange holds up a rectangular piece of yellow plastic two by a half centimetre in size. This plastic is hard and yet easy to recycle. At the molecular level, traditional hard plastics consist of long chains, linked together with chemical crosslinks. That makes them strong but also practically impossible to recycle, and therefore not sustainable. So Van Lange took a new approach: no chemical crosslinks but physical forces of attraction between the long chains. ‘I was obsessed with the idea of connecting the building blocks in an alternative way, and it worked,’ says the PhD candidate.

Van Lange and her colleagues gave one half of the chains, the building blocks of plastic, a positive charge, and the other half a negative one. If the two are brought together in the right way, they attract each other like magnets. The chains stay in place and you get a strong, hard plastic. But as soon as you heat it, the force of the attraction weakens and the plastic becomes malleable. ‘Then you can push it into a new shape or fill a hole in the plastic,’ says Van Lange.

Molecular umbrellas

It makes quite a difference how strong the attraction is between the molecular chains. Positive and negative particles naturally attract each other. When that happens in plastic, the result is superhard but also brittle material, discovered Van Lange. So she had to weaken the charge, and she managed that using a kind of molecular umbrella that partially shielded the charge in the plastic. ‘Like that we achieved a level of attraction that means the plastic doesn’t break easily and yet is easy to reshape using heat.’ Those little umbrellas are also water-resistant, so the plastic doesn’t weaken if it gets wet. ‘Charged material is nearly always water-sensitive, so it’s really surprising that we managed to do that.’

It would be great if we could process all plastics sustainably

The new plastic is not completely ready. ‘We have demonstrated that the concept of physical forces in plastic works, but now we need to find ways of making the material a bit more pliable,’ says the PhD researcher. She will devote some time to that during the final months of her research. She hopes to achieve it by reducing the total charge in the material, thus reducing the force of attraction. She is also considering using a different kind of building block for the plastic. ‘At present we are using polystyrene, which is quite stiff. If we switch to a more flexible variant, we might get a more pliable plastic.’

Although the new plastic is not ready for marketing yet, Van Lange hopes her work will already start to inspire her fellow researchers. It has shown that out-of-the-box thinking can produce really novel materials. ‘I’d like to motivate other scientists to take a new look at other materials and their molecules too,’ says Van Lange.

Sophie van Lange, a PhD candidate at Physical Chemistry and Soft Matter: ‘We have demonstrated that the concept of physical forces in plastic works, but now we need to find ways of making the material a bit more pliable.’ Photo Guy Ackermans

Sophie van Lange, a PhD candidate at Physical Chemistry and Soft Matter: ‘We have demonstrated that the concept of physical forces in plastic works, but now we need to find ways of making the material a bit more pliable.’ Photo Guy Ackermans