Anouk Lie-Piang, who recently obtained her PhD in Food Process Engineering, developed a model that predicts how so-called impure ingredients influence the structure of foodstuffs.

Food products are usually made up of various ingredients. These ingredients help give the product the desired shelf-life, flavour or texture. ‘One of the things we are working on in our research group is making ingredient production more sustainable,’ Lie-Piang explains.

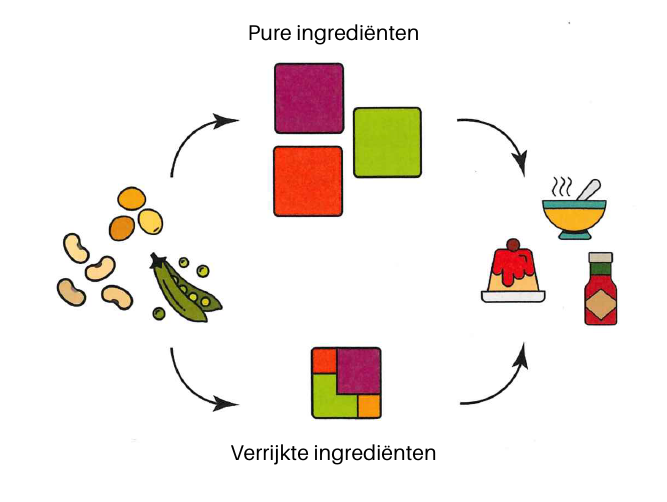

Pure ingredients

These ingredients are typically made from agricultural products such as wheat and soybeans. Producers usually split the crop into pure ingredients called isolates. Examples include wheat flour and soy protein.

Lie-Piang: ‘Every bag of isolates you buy contains exactly the same product. This makes them very attractive to the food industry because, with such standardised ingredients, manufacturers can easily create or reformulate recipes.’ The disadvantage of isolates is that it takes a lot of resources – such as water, chemicals and energy – to obtain such a pure ingredient.

Impure ingredients

Lie-Piang’s research focused on slightly less pure ingredients, which are still made up of multiple components. These impure ingredients are more sustainable because they have been subjected to fewer fractioning processes. At the same time, the fact that they consist of multiple components means they result in a less standardised end product, making them more difficult to use in the food industry. ‘In my research, I looked at how we can still use such impure ingredients for food products. I approached this issue from the angle of the functionality of the ingredients.’

Lie-Piang created a method that product developers could use to screen ingredients. ‘If you can predict the functionality of impure ingredients, for example, how “spreadable” or how gelatinous the ingredient will make the product, they can be used in a food product exactly like isolates. Then a food producer knows the end product’s properties.’

The end product is almost the same but is produced more sustainably

Anouk Lie-Piang, who recently obtained her PhD in Food Proces Engineering

Using Lie-Piang’s model, product developers can work backwards from their desired end product. ‘With a particular product in mind, you find out what ingredients you need and in what concentrations. The model then comes up with a list of options, which can be filtered in turn for sustainability or high concentrations of protein, for example.’

Predicting

In some cases, a product may require high-grade ingredients ‑ and, therefore, conventional production methods ‑ to arrive at the most sustainable option. Lie-Piang: ‘But less pure ingredients can often be quite useable too, and you can get the same functionality in a different way, so the end product is almost the same, but is produced more sustainably.’

Lie-Piang’s method relies on machine learning. ‘That is still an unconventional technique in the food industry. It is geared more towards predicting than understanding, but ultimately it is the food technologist who makes a decision based on the suggestions from the model. Our expertise is such that we know how systems are supposed to behave. That enables us to develop what you could call an expert-informed machine learning model.’

Peas and pea protein. Image Shutterstock

Peas and pea protein. Image Shutterstock